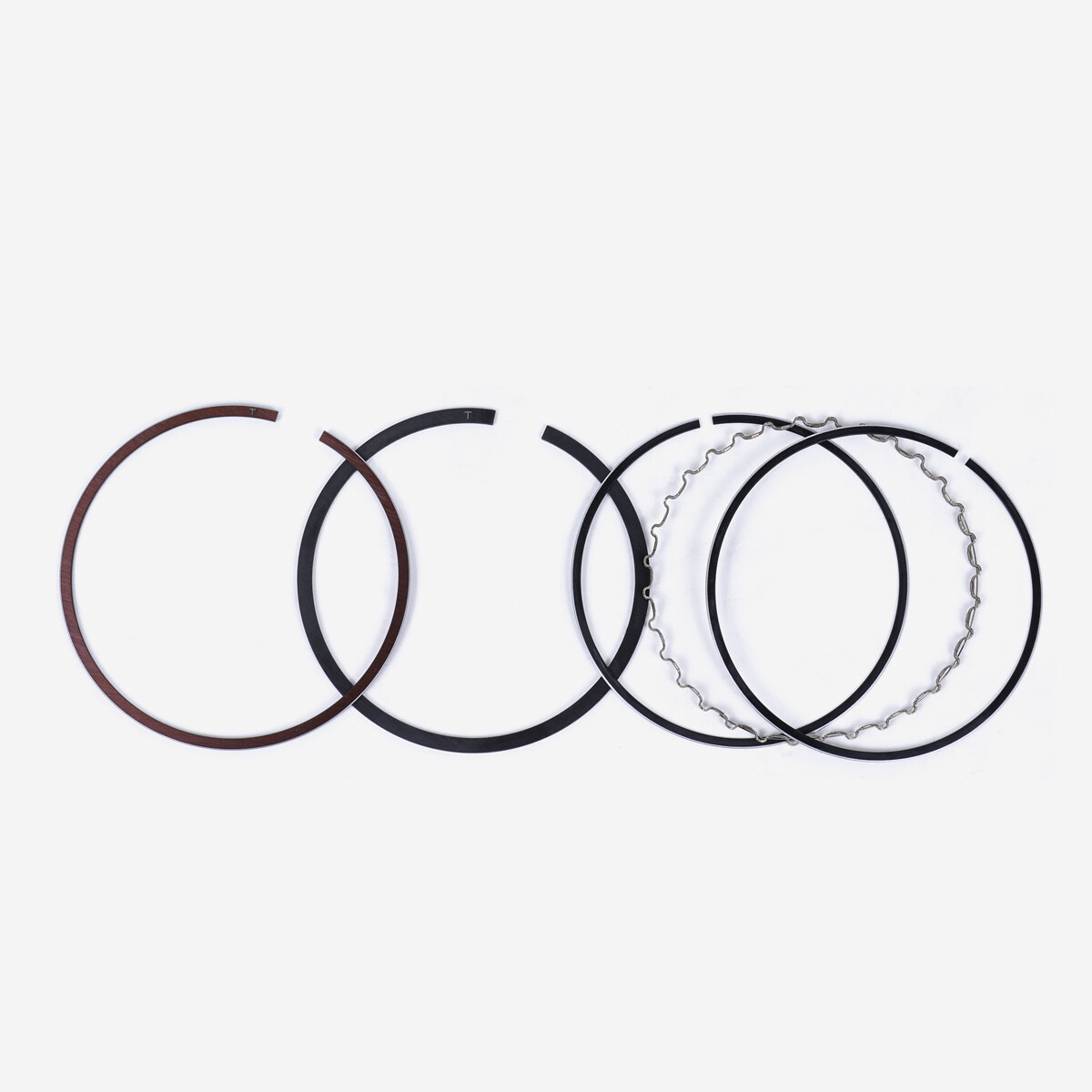

Piston rings are critical components in internal combustion engines, responsible for sealing the combustion chamber and ensuring optimal performance. Piston rings come in various designs and are made from different materials, each tailored to specific engine requirements and operating conditions. In this article, we will discuss the craftsmanship and material classification of piston rings.

Craftsmanship: Piston rings are typically manufactured using advanced machining techniques to ensure precise dimensions and smooth surfaces. The craftsmanship of piston rings involves several key processes, including profiling, grinding, lapping, and heat treatment. Profiling involves shaping the ring to the desired geometry, while grinding and lapping are used to achieve tight tolerances and a polished surface finish. Heat treatment is crucial for enhancing the strength and durability of the piston ring, ensuring it can withstand high temperatures and pressures in the engine.

Material Classification: Piston rings are commonly classified based on the materials from which they are made. The choice of material depends on factors such as engine type, operating conditions, and cost considerations. Some of the most common materials used for piston rings include:

If you need brand new high quality piston rings, we sincerely hope you choose us!

Whatsapp: +86 18144837660

Web: www.1doem.com

Email: onedauto@qq.com

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent